Darkling beetles, commonly referred to as litter beetles, are a widely encountered pest for those in the turkey production industry. When left uncontrolled, darkling beetles can multiple quickly, resulting in high populations that have many negative implications to poultry production objectives.

Damage Caused by Darkling Beetles

Beetles have chewing mouthparts, so the damage they cause is two-fold. Instead of transmitting disease-causing pathogens through a bloodmeal like a mosquito would, beetles are mechanical vectors of pathogens.

These types of vectors are insects that carry pathogens between hosts without becoming infected themselves, usually moving the pathogen on their bodies, feet, or hair. In poultry production, litter beetles may vector bacteria (Salmonella, E. coli), viruses (avian influenza), and intestinal parasites (cecal worms, tapeworms), among others.

In addition to their capacity to cause damage as vectors, litter beetles will cause damage to poultry facilities as they bore holes to pupate into the walls of the buildings. Over time, this causes reduced housing efficiency as it takes more to keep the house environmentally stable with a honeycomb of holes releasing heat.

Finally, turkeys that are grown among high populations of litter beetles suffer from agitation, reduced efficiency, and increased feed conversion.

In this economic climate, we strive to evaluate how producers can get the most out of essential insecticides and improve overall beetle control during long grow outs.

Darkling Beetle Best Practices

Using integrated pest management (IPM) and facility best practices alongside insecticide rotation and resistance management is the key to getting the most out of a pre-placement insecticide application.

Cultural Controls

Keep litter dry to reduce darkling beetles. Eliminate leaks in water lines and improve ventilation to reduce moisture content in litter.

Mechanical Control

Clean out and de-cake litter as often as possible. By removing old litter and replacing with fresh litter between flocks, you are removing most beetles from the facility, and reducing the moisture in the litter. Installing screens to the windows or vents of houses can eliminate large areas of beetle intrusion as they migrate from house to house.

Litter Management

If replacing litter between grow outs is not feasible, windrowing litter can drastically improve your beetle management program. Heat litter to 150° within five days to drive beetles from the litter to escape the heat. Treat the top of the litter rows with the insecticide currently in rotation. By forming this chemical barrier on top of the windrows and driving beetles across it with heat, you will increase kill and overall control of beetles going into the next flock.

Insecticidal Use in Turkey Facilities

Insecticides applied to the exterior premise or interior litter areas around a poultry facility are intended to provide relief from litter beetles in areas they frequent.

Premise treatments can be applied in areas where birds are not present and are designed to have longer residual effects. Formulations that include microencapsulated insecticides provide longer residual effects, as the active ingredients are released into the litter over an extended period.

Premise treatments can also contain quick-knockdown insecticides or insect growth regulators (IGR) that will help reduce the number of beetles in future generations. IGRs are insecticides that target immature stages of insects by inhibiting their development into adulthood. These are available in many formulations, such as granules and liquid premise applications. They help control future populations by reducing the number of beetle eggs, larvae, and pupae that make it to adulthood.

In extreme beetle infestations, you can apply insecticides over-animal to get relief before applying premise insecticides between flocks. Natural pyrethrin insecticides are excellent options for beetle control over-bird due to their low toxicity and flexible reapplication rates. Pyrethrins deliver a fast knockdown in a water- or oil-based concentration and often contain a synergist, such as piperonyl butoxide (PBO). Over-bird insecticides are usually applied through a mist or fog applications.

Insecticide Rotation

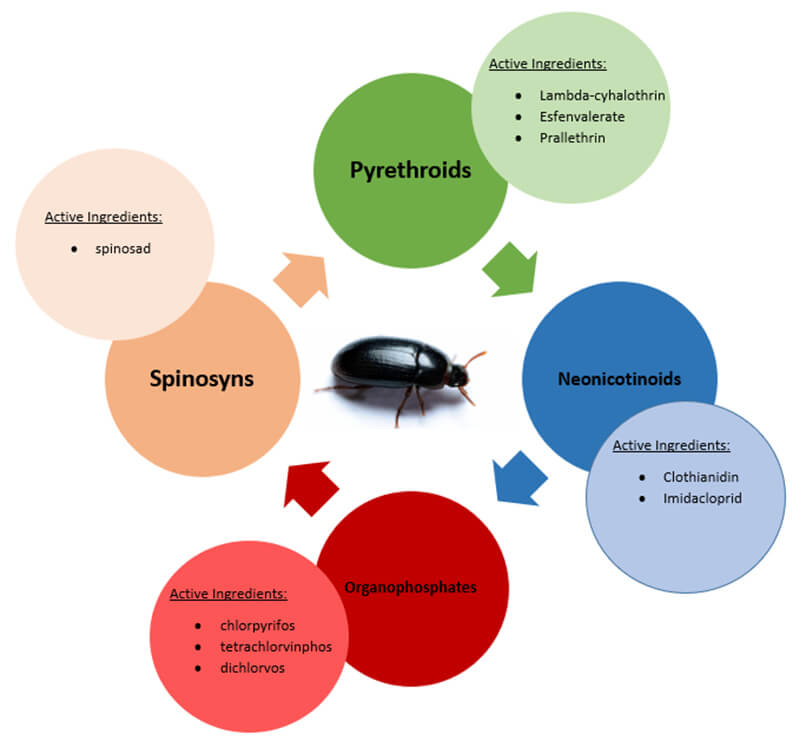

One of the most important factors in insecticide success is the rotation – or intentional change – in insecticide class.

Continual use of the same insecticide class can quickly lead to resistance, or the reduced ability of that insecticide to kill insects. For beetle control, it is recommended that insecticide classes be rotated 2 -3 times per year depending on application frequency.

Communicate Management Plan

Litter beetle management plans are most successful when they are written down and posted at a facility. Outlining the practices you hope to implement, such as windrow practices, litter management and insecticide rotations, can help make sure everyone who maintains the turkey production facility is focused on the same goal.

By developing a well-rounded litter beetle management program, you can reduce your insecticide use, increase bird efficiency, and improve your bottom line.

Additional Resources: