How does droplet size affect your fogging application? Take a look at this article to find out!

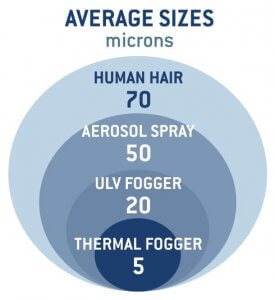

Each type of spray pattern has a specific micron size associated with it. And the micron size can affect an application of insecticide in some important ways:

Each type of spray pattern has a specific micron size associated with it. And the micron size can affect an application of insecticide in some important ways:

- The larger the droplet size the quicker it will fall out of the air and onto a surface.

- The smaller the droplet size the longer it will remain suspended in the air before it falls onto a surface.

Some factors that affect droplet size are pressure, viscosity, fluid temperature, and surface tension. Increased pressure and increased fluid temperature both decrease droplet size. Increased viscosity and increased surface tension both decrease droplet size.

Knowing these factors, you can increase or decrease the droplet sizes to suit the specific needs for each situation.

| Spray Pattern | Micron Size Range |

| Course Spray | 400 and larger |

| Fine Spray | 100 – 400 |

| Mist | 50 – 100 |

| Aerosols & Fogs | 0.1 – 50 |

| Fumes & Smokes | 0.001 – 0.1 |

Droplet Size Impacts Indoor and Outdoor Treatments

Droplet size is important outdoors where drift onto non-target areas can occur. The very small size of droplets produced with fogging make it difficult to ensure the product does not drift into an area where you don’t want it to go. Always be aware of the wind speed if you are fogging outdoors.

Obviously indoors, a fogging application is less likely to drift off target. However, with the lack of air flow while fogging indoors, proper PPE is essential. You can’t stand up-wind of the fog in an enclosed space!

But the long hang time of the smaller droplets can be beneficial for targeting flying pests and to get into spaces other applications might not be able to penetrate.

Learn More:

Photo Credit: Michal Matlon on Unsplash